Zagar Feed Unit Accessories can Streamline your Manufacturing

If you use a Feed Unit in your manufacturing shop, you could speed up production with the right accessories. Manufacturers know the value of a feed unit. For those who don’t know, a feed unit is defined by Modern Machine Shop as “an automated modular machining unit usually consisting of two axes of motion – spindle rotation and linear feed.”

Zagar Feed Units, used in the right applications, can be more cost-effective than CNC (Computer numerical control). Shops just need to understand the variables involved, in order to save frustration and to avoid slower production rates. For instance, a ballscrew feed unit enhances not only tool life but also hole quality when drilling with a carbide tool. The ballscrew feed unit is able to maintain a consistent feed rate and chip load, which make it ideal for this purpose. But for a tool such as a deburring bit or a friction drill, a pneumatic or hydraulic piston type of feed unit, with its constant force feed, may offer a better solution.

Zagar Inc. is driven to provide the complete solution, so all Zagar multiple spindle heads mount on all Zagar feed units That way, the resulting set-up is smoother and the production and operation is more efficient. Zagar is focused on making your production more efficient without increasing your costs. Zagar has an incredible line of products, but also encourages direct consultation with engineers helping you to design a complete machine system, that is specific to your needs. To find out more about Zagar Products and capabilities, call (216)731-0500 or visit us at Zagar Inc. on ResourceShark.com. To learn more about Feed Units, keep reading here.

Mechanical Feed Units produced by Zagar Inc.

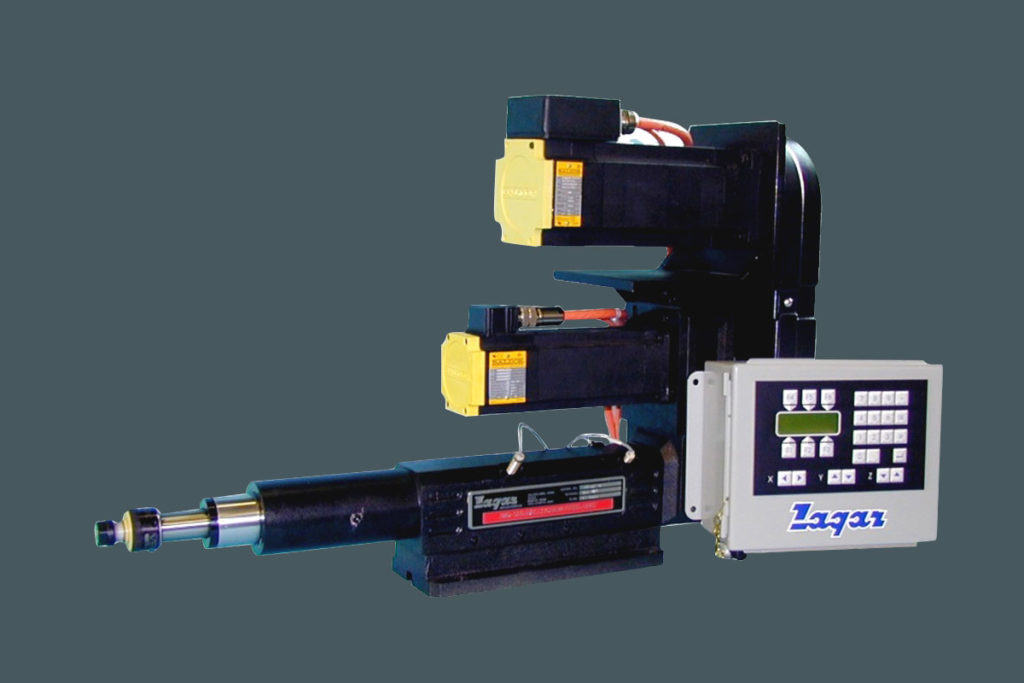

Ballscrew Feed Unit. Zagar ballscrew feed units are actuated through a servo motor. The added flexibility of the units combined with the one- or two-axis fully programmable servo control packages that Zagar provides creates limitless applications.

Cam Feed Unit. This unit, intended for production applications with static operation parameters, features a 200:1 gear reduced feed cam rotated by an electric brake motor which also operates the spindle delivering the solid consistency in product manufacturing you need.

Gear Driven Feed Unit/Lead Screw Tapping Unit. Zagar Lead Screw Tapping Units are powered by a gear reduced, reversing brake motor and feed with a Zagar lead screw. Lead Screw Tapping units are designed for deep hole drilling or special purpose applications. Lead Screw tapping units, were originally developed for accurate precision holes in metal, such as for the barrel of a gun. Today the uses are wide and varied, but usefulness of the Lead Screw Tapping Unit remain.

Note: If your product is guns, be sure to recommend quality gun cleaning products like those offered by Pro-Shot Products.

Feed Unit Control Options.

Zagar Inc. offers servo control packages to operate any of the Thruster drilling or tapping feed units and the MQ Ballscrew Feed Unit. Each control package is designed to meet the increasing capability of the Feed Units. Zagar Inc prides itself on providing you with the best servo control package available that not only meets your high performance needs, but does so at an affordable price.

Feed Unit Accessories

A few of the feed unit accessories that enable additional capability and use flexibility offered by Zagar Inc. include:

mounting options like the column mount for mounting on horizontal surfaces or the barrel mount for installation over the edge of walls, shoring cans or other structures.

feed control options such as a peck module or a CVC hydraulic control cylinder.

tool holders, including the ASA adapter, the TMS quick change tap holder, precision keyless drill chuck, Jacobs taper drill chuck, Zagar z-lock, or Zagar collet & nut.

lead screw kits, either lead screw, or lead screw nut to translate motion of machine.

spindle options and so many other accessories that customize your installation and enhance efficiency of machines in your shop. Visit Zagar Inc. on ResourceShark.com and click on contact to set up your consultation with a Zagar application engineer to determine the right combination for your production.