The Adaptability of Zagar Machining Heads

Machining heads from Zagar inc. are created to use on your sophisticated, increasingly multi axis machines for high production drilling and tapping. An Intricate part of subtractive manufacturing industry, these multi spindle heads can be custom made in innumerable spindle pattern configurations to meet specific manufacturing needs. Engineered for Flexibility, Zagar heads can be configured to adapt to different vertical or horizontal CNC machining centers equipped with BT, CAT and HSK spindle connections. Managing multiple drill and tap spindles, these CNC milling heads handle hole diameters up to .500 inch with little human supervision needed.

Machining heads from Zagar inc. are created to use on your sophisticated, increasingly multi axis machines for high production drilling and tapping. An Intricate part of subtractive manufacturing industry, these multi spindle heads can be custom made in innumerable spindle pattern configurations to meet specific manufacturing needs. Engineered for Flexibility, Zagar heads can be configured to adapt to different vertical or horizontal CNC machining centers equipped with BT, CAT and HSK spindle connections. Managing multiple drill and tap spindles, these CNC milling heads handle hole diameters up to .500 inch with little human supervision needed.

Problem solving features open the Zagar multi spindle machining heads up for a wide range of applications. These powerful heads feature Working spindles on axis of rotation. This multiple spindle unit features an adjustable axis of rotation for use as the basis of coordinate measuring machines and has very precise movement. Zagar quality, hardworking machining heads deliver accurate results in high speed, high production, and high repeatability with little down time.

Variable spindle lengths allow multiple interior drilling and tapping cuts to occur simultaneously, saving human interaction requirements.

Orientation lock mechanism (adjustable to various positions).

This mechanism for unlocking and locking the orientation of the machining head ensures accurate positioning and prevents human error.

High quality hardened gears that withstand high production applications. Reliable quality workmanship that delivers speed, functionality, accuracy without sacrificing high repeatability.

Optional bushing plates

When you opt for this feature, Zagar delivers precise, heavy duty bushing plate assemblies for large scale production. Bushing plates are available as a standard kit or customized to your application and are made here in the USA.

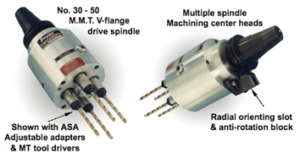

The precision multiple spindle tooling of this unit is compatible with automatic tool changers on machining centers. Zagar machining heads are available with MMT V-Flange, straight shank, and HSK taper drive spindles. Current options include through the spindle coolant, quick change tool holders, and increased operating speeds. Accessories are included to adapt your machining center for use with multi-heads (radial orientation).

Standard heads range in size from 6″ to 10″ outside diameter. Smaller heads are available down to less than 2″ in diameter. Larger heads are manually loaded in most cases and supplied to suit. The largest to date, operates four 1″ end mills at 10,000 RPM (25 HP per spindle).

A History of Quality Engineering Continues Today

Zagar is proud of its innovative machining center multi-spindle drill and tap heads engineered for high speed, high feed, drilling and tapping for a wide array of industries like automotive, aerospace, appliance, electronics and woodworking. Machining center heads are customized to numerous configurations in order to meet particular manufacturing requirements.

For years, Zagar Multi-spindle heads have enhanced the efficiency of machines centers around the world through proprietary gearless technology. This technology allows Zagar to create products capable of drilling random patterns with extremely close centers on the spindles. Zagar machining center heads are engineered to adapt all types of machining centers and drives.

Zagar Inc. is proud to have improved American productivity for over seventy five years with a range of multi-spindle drill and tap heads, feed units, workholding solutions and robotic end effectors.