Zagar is Serious about Workholding

Zagar Takes Workholding Seriously

Zagar specializes in hydraulic, pneumatic and high production drilling and tapping machines and related equipment. Without workholding fixtures, drilling and tapping machines lose efficiency. Zagar Inc. takes workholding seriously. They are so serious about workholding, Zagar formed a division to focus directly on workholding vises, fixtures and more. Workholding fixtures by Zagar are produced to perform a variety of tasks.

Vises

Vises are precision tools, holding workpieces with a consistently higher gripping force, while maximizing machine productivity. They provide deeper cuts at higher feed rates and are especially useful with milling machines, lathes, drilling and tapping machines. Zagar vises used on a large scale, hold workpieces during machining operations and can support tight tolerances. It is critical that vises are designed to be rigid yet flexible, cost effective and durable. Zagar vises are all of those things and more. Need still more? Additional clamping force can be achieved with the use of a hydra-mechanical machining vise. Zagar vises function in a variety of jaws; from flat jaws, downthrust, angular, swivel and diagonal clamping jaws.

Get the safety, speed and accuracy you need with a quality vise from Zagar Inc.

Rotary Tables

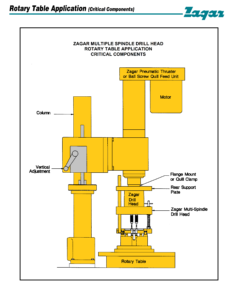

Rotary Table for Zagar Multi Spindle Drill

Rotary tables come in numerous diameters and feature auto home switches, pneumatic and hydraulic brakes, CNC integration and stand-alone controls. Zagar‘s complete line of rotary and indexing tables can be with right hand or back-mounted AC or DC motors. Tables come in standard diameters from 4.72 to 12.6 inches (120 to 320 mm). Special large sized tables are available up to 117 inches.

All Zagar rotary tables offer auto home positioning and pneumatic brake systems. Precision bronze/nickel worm wheel and case hardened steel worm gear ensure long term indexing accuracy. The tables contain a dual pitch worm shaft that allows easy backlash adjustment. They feature a one piece faceplate and spindle design for rigidity, have a gear ratio of 90:1 for high speed feed rate. A back mount motor design is available to facilitate tight mounting space in small drilling and tapping CNC machining centers.

Compatibility

Zagar tables integrate with most 4th and 5th axis CNC controls and servo motors. An indexing controller using industry standard programming functions with any CNC or manual machine tool. Motors are quoted to match machine tool configurations or to provide independent performance ensuring accuracy precision and repeatability. Designed for easy onsite installation, Zagar tables are programmable with conversational software, g-code or CAD-CAM.

Fixtures

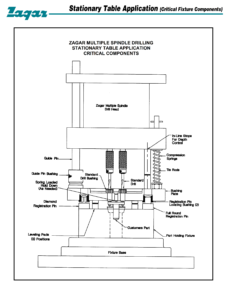

Stationary Table – Critical Fixture

Fixtures for special part holding configurations, including tombstone styles, are manufactured for precise repeatability. Available in manual and automatic styles, all workholding fixtures operate with the fixed position collet in the design. Zagar Collet fixtures install quickly and easily for almost every machining operation used today. Air or hydraulic operated, Zagar fixtures hold round, square and hex, as well as many contoured shapes.

Collets and Collet Chucks

Numerous collet designs are available for both internal and external grip, holding round, square, hex, and even many contoured shapes. 5c collet fixtures by Zagar Inc. offer superior concentricity and faster setup than 3-jaw chucks. Collet blocks can be grouped to save time and labor. Zagar collet fixtures enable equipment like VMCs, HMCs and jig grinders to machine multiple workpieces unattended over long periods. Imagine the improvement to your productivity and bottom line.

Quality 5c collets to fill your shop needs for mill and lathe work are available at zagar.com. Or call (216) 731-0500 and tell us what you need. We’d love to talk about your next collet fixture, multi collet fixture, or custom workholding fixture.

Zagar Workholding Solutions

Improving American productivity for over eighty years, Zagar manufactures and distributes a range of workholding solutions. Additionally, multi-spindle drill and tap heads, feed units and robotic end effectors are all available at Zagar.com or (216) 731-0500. Our expertise is in machining both ferrous and non-ferrous materials, in hydraulic, pneumatic and high-production drilling/ and tapping. Our customers are in a range of industries from automotive to medical equipment. Find out more at www.zagar.com or call us at (216) 731-0500 today.

Article submitted March 8, 2021

By Jo Gardner for Zagar Inc.